Shandong WoSealda New Material Technology Co., Ltd.

Curtain wall and hollow Application domain solutions

Curtain wall and hollow

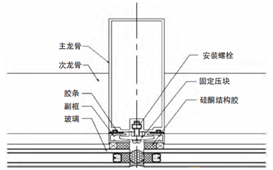

Silicone sealant is a paste made of polydimethylsiloxane as the main raw material, supplemented by crosslinking agent, filler, plasticizer, coupling agent and catalyst in vacuum. It forms elastic silicone rubber by curing with water in the air at room temperature. Silicone glass adhesive has strong adhesive force, high tensile strength, weather resistance, vibration resistance, moisture resistance, odor resistance and large changes in cold and heat. In addition to its wide applicability, it can realize the bonding between most building materials products, so it has great application value. Silicone sealant is mainly used for structural assembly of curtain wall and caulking of glass curtain wall and stone curtain wall in curtain wall engineering.

硅酮结构胶用于幕墙结构性装配

硅酮耐候胶用于玻璃幕墙的嵌缝

硅酮石材胶用于石材幕墙的嵌缝

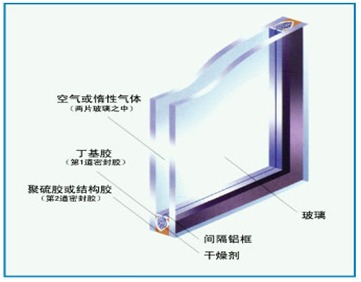

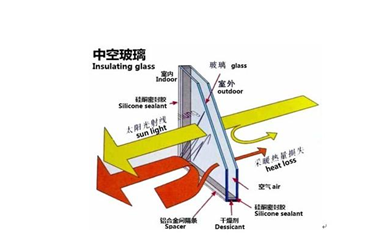

It is a new building material with good sound insulation, heat insulation, frost prevention, moisture-proof, high wind pressure resistance, beautiful and applicable, and can reduce the self weight of the building. It is a high-efficiency sound insulation and heat insulation glass made by bonding the glass with the aluminum alloy frame containing drying agent with two (or three) pieces of glass and high-strength and high air tightness composite binder.

glass screen wall

The appearance is light and beautiful, not easy to pollute and save energy. The room is warm in winter and cool in summer, which greatly improves the living environment. Insulating glass has many advantages over ordinary double-layer glass, so it has been recognized by countries all over the world, and the amount is increasing. The corresponding demand for two-component silicone sealant is also increasing.

The main function of hot melt butyl adhesive in insulating glass is to prevent water vapor or inert gas from entering and leaving the glass cavity, and provide a certain shear strength and bonding strength.

Two component silicone hollow adhesive is mainly used for secondary sealing of insulating glass. The product has high strength, high adhesion, excellent weather aging resistance, high and low temperature resistance, ozone resistance, ultraviolet resistance, water resistance, large joint displacement resistance, rapid curing, no pollution, and excellent performance of the product.

Two component silicone hollow adhesive is mainly used for secondary sealing of insulating glass

Polysulfide sealant can also be used for secondary sealing. Js-998 polysulfide sealant for two-component insulating glass is a solvent-free, two-component, room temperature curing sealant.

Js-998 has good adhesion to glass, aluminum alloy, galvanized steel and other materials. Good adhesion to on-line Low-E glass; For off-line Low-E glass, due to the need for film removal at the edge, and the different materials and film removal processes of the film removal wheel, the compatibility test shall be carried out first.

Js-998 viscosity can be adjusted according to equipment and environmental changes. It is generally applicable to automatic hollow glass production line (mechanical construction) and manual production line (manual construction).

Product features:

Two component, room temperature curing

Good adhesion

Excellent aging resistance, very low water vapor permeability

It does not contain solvents and low boiling point substances and does not pollute the environment